Why Carbon Deposits Form in the Combustion Chamber of GDI Engines and Maintenance Recommendations

Share

Gasoline Direct Injection (GDI) engines are renowned for their improved fuel efficiency, enhanced power output, and lower emissions compared to traditional port fuel injection (PFI) engines. However, one of the challenges that come with GDI technology is the formation of carbon deposits in the combustion chamber. Understanding the reasons behind this issue and how to manage it is essential for maintaining the performance and longevity of GDI engines.

Why Carbon Deposits Form

-

Direct Injection Design: In GDI engines, fuel is injected directly into the combustion chamber at high pressure. This differs from PFI engines, where fuel is mixed with air in the intake manifold before entering the combustion chamber. The direct injection design allows for better fuel atomization and precise control over the air-fuel mixture, but it also means that the fuel does not wash over the intake valves, leaving them and the combustion chamber vulnerable to carbon buildup.

-

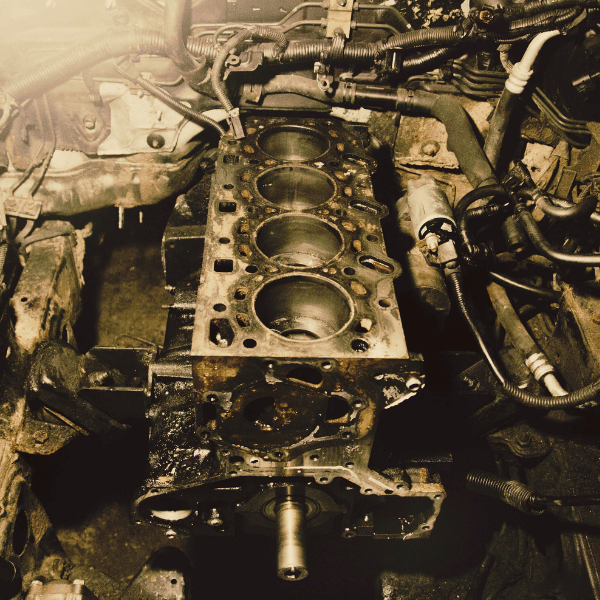

High Combustion Temperatures: GDI engines typically operate at higher pressures and temperatures to achieve better efficiency and performance. These high temperatures can lead to incomplete combustion of fuel, resulting in the formation of carbon deposits on the piston tops, cylinder walls, and combustion chamber surfaces.

-

Blow-by Gases: During the combustion process, some gases can escape past the piston rings and enter the crankcase, a phenomenon known as blow-by. These gases, which contain unburned fuel and oil vapors, are recirculated back into the intake manifold via the Positive Crankcase Ventilation (PCV) system. Over time, this can lead to the accumulation of carbon deposits in the combustion chamber.

-

Oil Seepage: Oil can seep past the valve stem seals and into the combustion chamber, especially in engines with higher mileage. When the oil burns, it leaves behind carbon deposits, contributing to the overall buildup in the combustion chamber.

Consequences of Carbon Deposits

The accumulation of carbon deposits in the combustion chamber can lead to several problems, including:

- Reduced Engine Performance: Carbon deposits can disrupt the airflow and fuel mixture, leading to decreased engine power and responsiveness.

- Increased Fuel Consumption: Inefficient combustion caused by carbon deposits can result in higher fuel consumption.

- Engine Knocking: Carbon buildup can increase the compression ratio, leading to engine knocking or pinging, which can damage the engine over time.

- Higher Emissions: Incomplete combustion due to carbon deposits can result in higher emissions, affecting the environment and potentially causing the vehicle to fail emissions tests.

Maintenance Recommendations

To prevent and manage carbon deposits in the combustion chamber of GDI engines, consider the following maintenance tips:

-

Use High-Quality Fuel Additives: Regularly use high-quality fuel additives designed for GDI engines. Berryman Intake Valve and Combustion Chamber Cleaner is an excellent choice. Professionally formulated for use in all fuel-injected gasoline engines, it contains polyetheramine (PEA) to clean combustion chambers and all types of intake valves, including those in PFI, TBI, and GDI engines. This cleaner dissolves stubborn carbon buildup, resulting in a dramatic increase in performance and overall drivability. It restores original octane requirements, includes universal application accessories, and is safe for catalytic converters and oxygen sensors. Note that it is not for use in diesel engines.

-

Periodic Engine Cleaning: Have your engine professionally cleaned at regular intervals. This can involve chemical cleaning or using specialized equipment to remove carbon deposits from the combustion chamber and intake valves.

-

Regular Oil Changes: Follow the manufacturer’s recommendations for oil change intervals. Clean oil reduces the amount of oil vapors that can contribute to carbon buildup.

-

Proper Engine Operation: Avoid short trips and excessive idling, which can lead to incomplete combustion and carbon buildup. Occasionally driving at higher speeds can help burn off deposits and keep the engine clean.

-

Install an Oil Catch Can: An oil catch can in the PCV system can capture oil vapors and prevent them from reaching the combustion chamber.

By understanding the causes of carbon deposits and following these maintenance recommendations, you can help ensure your GDI engine runs smoothly and efficiently for many years. Regular maintenance not only prevents costly repairs but also maximizes the performance and longevity of your engine.