Diagnosing Common Diesel Engine Failures: Causes, Prevention, and How a Quality Lubricant Can Make the Difference

Compartir

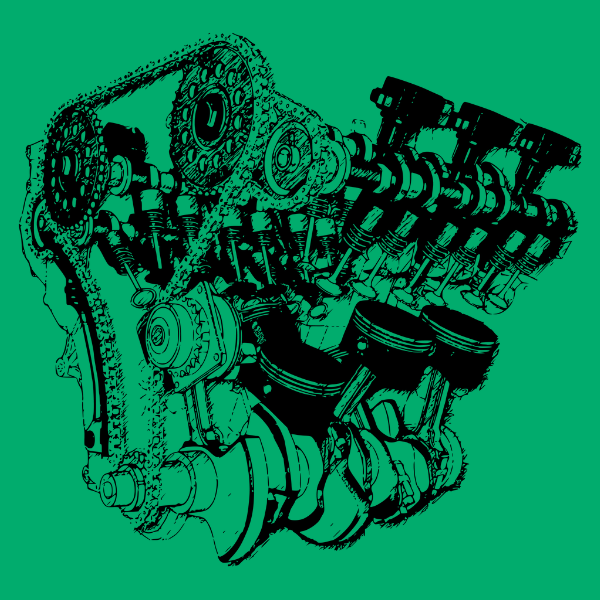

The diesel engine is synonymous with power, durability, and efficiency in commercial and heavy-duty applications. However, even the most robust machinery can experience issues without proper maintenance. Timely failure diagnosis is key to avoiding costly repairs and extending the engine’s service life.

In this article, we’ll break down the most common diesel engine failures, how to identify them, and the role that high-performance lubricants like Ridgeline SB 15W-40 CK4 play in preventing them.

1. Common Diesel Engine Failures and How to Spot Them

1.1 Loss of Power

Symptoms: Slow acceleration, difficulty maintaining speed uphill or under load.

Causes: Clogged air or fuel filters, injection system problems, low compression, or excessive soot buildup in the engine.

Prevention: Keep filters clean and perform regular injection system inspections.

1.2 Excessive Oil Consumption

Symptoms: Oil levels drop quickly between services.

Causes: Worn piston rings, damaged valve seals, or using a low-quality oil that lacks consumption control.

Prevention: Use lubricants specifically formulated for oil consumption control, such as Ridgeline SB 15W-40 CK4, which offers exceptional consumption control and wear protection.

1.3 Overheating

Symptoms: High readings on the temperature gauge, power loss, and potential engine shutdown.

Causes: Cooling system issues, low coolant levels, or deposit buildup that impairs heat dissipation.

Prevention: Maintain the cooling system regularly and use oils with high oxidation stability, like Ridgeline SB 15W-40 CK4, which helps keep the engine clean and deposit-free.

1.4 Excessive Smoke (Black, Blue, or White)

- Black: Incomplete combustion (misadjusted injection or dirty air filter).

- Blue: Oil burning (internal wear).

-

White: Coolant entering the combustion chamber (possible head gasket damage).

Prevention: Check injection settings, keep the intake system in good condition, and use a lubricant with excellent soot-handling capability, like Ridgeline SB 15W-40 CK4.

1.5 Unusual Noises

Symptoms: Metallic knocking, rattling, or abnormal humming.

Causes: Low lubrication, bearing wear, or internal component damage.

Prevention: Monitor oil levels and use lubricants that provide superior wear protection.

2. The Critical Role of Lubricants in Failure Prevention

Engine oil is more than just a lubricant—it’s a critical element for protection, cleanliness, and efficiency.

A product like Ridgeline SB 15W-40 CK4 delivers essential benefits for preventing and diagnosing failures:

- Full compatibility with modern technologies such as EGR and ACERT, reducing the risk of corrosion and soot buildup.

- Superior deposit control to keep pistons and internal components clean.

- Outstanding oxidation stability to prevent oil thickening at high temperatures.

- Excellent wear protection for extending the life of critical parts.

- Exceptional soot-handling capability, vital for preventing lubrication system blockages.

3. Preventive Maintenance: The Best Tool Against Failures

Failure diagnosis must go hand-in-hand with a preventive maintenance plan that includes:

- Regular oil checks and changes according to the manufacturer’s recommendations.

- Using high-performance oils like Ridgeline SB 15W-40 CK4, meeting the latest API CK-4 specifications and replacing CJ-4, CI-4 Plus, and earlier categories.

- Monitoring oil consumption and performing used-oil analysis to detect internal wear.

- Periodic inspection of the injection and intake systems.

- Cleaning the cooling system to prevent overheating.

Fast, accurate diesel engine failure diagnosis not only prevents costly repairs but also ensures operational continuity. Incorporating an advanced lubricant like Ridgeline SB 15W-40 CK4 into your maintenance routine helps prevent issues, optimize performance, and extend engine life—even under the toughest operating conditions.